How Seasonal Changes Impact Dye and Pigment Performance

Understanding Seasonal Variability

The performance of dyes and pigments is not static; it changes with the seasons. Factors such as temperature, humidity, and UV exposure can significantly alter how these substances behave. As we transition from one season to another, manufacturers and users of dyes must understand these changes to maintain consistent quality and performance.

Temperature fluctuations can affect the chemical stability of dyes. In colder months, certain dyes may experience reduced solubility, impacting their effectiveness. Conversely, high temperatures can accelerate chemical reactions, potentially leading to fading or discoloration.

Temperature: A Crucial Factor

Temperature impacts the viscosity of dye solutions. During winter, lower temperatures can increase viscosity, making it challenging to apply dyes uniformly. This is particularly relevant in industries like textiles where uniform coloration is crucial.

Conversely, elevated temperatures in the summer can lead to faster drying times. While this may be beneficial for some processes, it can pose a challenge for others requiring more controlled application and drying times.

The Role of Humidity

Humidity levels fluctuate greatly with the seasons and can have a profound effect on dye performance. High humidity tends to lower the evaporation rate of solvents in dye solutions, which can lead to longer drying times and potentially uneven application.

In contrast, low humidity conditions often found in winter can lead to rapid solvent evaporation. This quick drying might cause surface crusting before the dye penetrates fully into materials, resulting in patchy coloring.

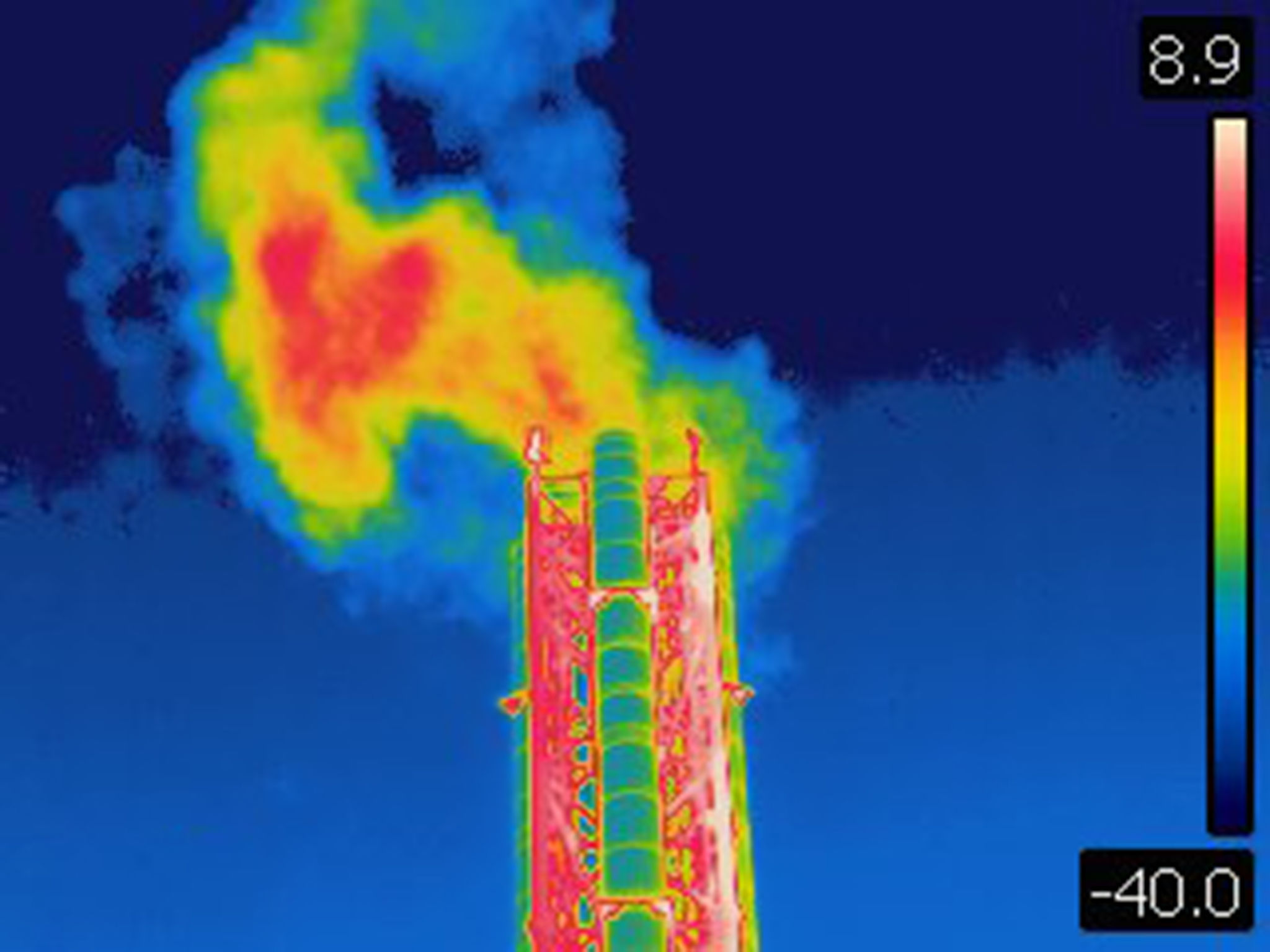

UV Exposure and Its Implications

UV exposure varies with the seasons and can significantly affect dye and pigment stability. During summer months when UV radiation is intense, dyes are more prone to photodegradation. This process can lead to fading, especially in outdoor applications like paints and coatings.

Protective measures such as UV stabilizers or coatings can help mitigate these effects. However, understanding the seasonal variance in UV exposure is crucial for planning outdoor projects that rely on color fastness.

Practical Solutions for Seasonal Challenges

To combat these seasonal challenges, businesses can employ several strategies:

- Adjust formulations: Tweaking chemical compositions to suit seasonal conditions can help maintain performance.

- Storage considerations: Proper storage conditions tailored to each season can preserve dye and pigment integrity.

- Environmental controls: Implementing environmental controls in production areas to stabilize temperature and humidity levels.

By acknowledging and planning for these seasonal variations, industries reliant on dyes and pigments can ensure consistent quality year-round. Embracing these strategies not only improves product performance but also enhances customer satisfaction and brand reputation.